НАНОМАТЕРИАЛЫ

И УСТРОЙСТВА

ООО "Наноматериалы и устройства" имеет доступ к широкому классу станков с ЧПУ в регионе и за его пределами, обладает обширной сетью партнерских связей, готова вести реализацию изделий любой сложности из нержавеющей стали, алюминия, титана и молибдена.

Перечень металлообрабатывающих центров, к которым имеется постоянный доступ:

Вертикально-фрезерный обрабатывающий центр c ЧПУ VF-2 (Haas Automation) с поворотным столом HRT 210

Вертикально-фрезерный станок от компании Haas отличается характеристиками, позволяющими качественно, с высокой чистотой выполнять металлообработку различных материалов. ЧПУ, устанавливаемое на оборудование, обеспечивает его высокую производительность. Удобство работы определяется возможностью просмотра микрокоманд на жидкокристаллических экранах, которыми оснащаются все модели вертикально-фрезерных станков. Фрезерный обрабатывающий центр Haas VF-2 способен выполнять достаточно широкий перечень различного рода задач: обработку поверхностей, изготовление пресс-форм, снятие фаски по контуру и т.д. Что касается возможностей работы с различными материалами, то вертикально-фрезерный станок Haas может использоваться для обработки деталей, изготовленных из таких материалов как сталь, титан, алюминий, сплавы.

Технические характеристики

Параметры рабочей зоны

Максимальное расстояние от стола до торца шпинделя

Минимальное расстояние от стола до торца шпинделя

Длина стола

Ширина стола

Максимальная нагрузка на стол (равномерно распределенная)

Ширина Т-образных пазов

Расстояние между Т-образными пазами

Параметры шпинделя

Шпиндель

Конус ISO 40

Прямой привод

Параметры перемещений рабочих органов

Величина рабочих перемещений по осям X Y Z

Максимальная величина рабочих подач

Максимальная скорость холостых перемещений рабочих органов

Параметры устройства ЧПУ

Тип устройства

Количество управляемых осей

Скорость обработки программ

Тип интерфейса для подключения съемных носителей памяти

Точность позиционирования

Параметры рабочей зоны

Максимальное расстояние от стола до торца шпинделя

Минимальное расстояние от стола до торца шпинделя

737 мм

102 мм

1219 мм

457 мм

1588 кг

16 мм

80 мм

10000 об/мин

ISO 40

22,4 кВт

762 мм x 406 мм x 508 мм

16,5 м/мин

25,4 м/мин

Haas CNC

3

до 1000 блоков/сек

USB

±0,0050 мм

737 мм

102 мм

Параметры управления ЧПУ

-

ISO программирование в G-кодах;

-

графическая 2D визуализация;

-

17 встроенных стандартных циклов обработки;

-

текстовый редактор управляющих программ;

-

круговой многофункциональный JOG-маховичок;

-

калькулятор для расчета режимов резания и геометрии;

-

мониторинг режущего инструмента по нагрузке и стойкости;

-

функция компенсации инструмента с возможностью учета износ;

-

метрическая и дюймовая система;

-

возможность продолжения программы с любого кадра;

-

5 дополнительных М-функций для вспомогательного оборудования.

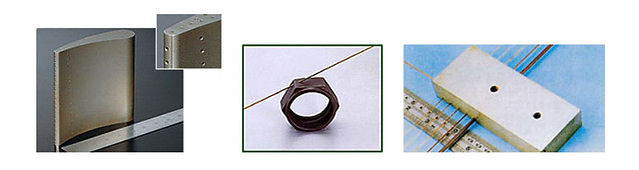

Электроэрозионный проволочно-вырезной станок MV1200S Advance (Mitsubishi Electric)

Cильной стороной электроэрозионных станков с ЧПУ является возможность обработки нестандартных материалов, труднообрабатываемых (твердый сплав, ПКД, кубический нитрид бора, углеситаллы и многие другие). В основном станки применяются для удовлетворения нужд индустриальных производств – изготовление штампов, оснастки для литья пластиков и металлов; в медицинской промышленности, часовой и аэрокосмической промышленности.

Технические характеристики

Максимальный размер заготовки

Максимальный вес заготовки

Размер стола

Перемещения по осям (X/Y/Z)

Перемещения по осям (U/V)

Угол наклона проволоки/высота детали

Наилучшая шероховатость

Точность, достигаемая на детали

Диаметр проволоки

Вес катушки с проволокой:

Минимальное отверстие для автозаправки

Диэлектрик

Генератор импульсов

Максимальный рабочий ток

Система управления

Объем бака диэлектрика

Степень фильтрации рабочей жидкости

Количество фильтров

Объем баллона для ионообменной смолы

Компрессорная система охлаждения диэлектрика

Полная подключаемая электрическая мощность

Активная потребляемая электрическая мощность/ в режиме «сна»

Давление сжатого воздуха

Макс. расход сжатого воздуха

810x700x215 мм

500 кг

640x540 мм

400x300x220 мм

120x120 мм

15°/200 мм, 30°/87 мм

Ra 0,25 мкм

±0,002 мм

0,1–0,3 мм

10(20/50) кг

0,5 мм

деонизированная вода

антиэлектролизный V350V с полностью цифровым управлением DAE II

50 А

MITSUBISHI ADVANCE (64 разряд., RISC технологии), со встроенным 3D/2D CAM, RAM 1ГБ

550 л

3–5 мкм

2

10 л

Стандарт

13,5 кВА (3 фазы, 400±10% В)

6,0/0,8 кВт

0,5–0,7 МПа

40–75 л/мин

Дополнительные опции

-

HSP1200 — пакетная опция High Spec Package для MV-1200S, включает: замкнутый стол, ЦЛД и оптические линейки по осям UV, планировщик задач, Corehold Function, цифровой сенсорный датчик давления фильтрации для визуализации на экране монитора и датчик контроля потребления электроэнергии для подсчета себестоимости обработки и настройки энергосбережения;

-

3D CAM — встроенный программный модуль для работы с 3D-моделями дополнительно к стандартному 2D CAM.

Электроэрозионный станок для стартовых отверстий AD24 (Advanced Machinery EDM)

Высокоскоростные электроэрозионные сверлильные станки Advanced Machinery EDM предназначены для сверления глубоких отверстий малого диаметра в различных токопроводящих материалах, таких как закаленная сталь, нержавеющая сталь, твердый сплав, медь, алюминий и другие. Электроэрозионное сверление осуществляется трубчатым электродом с вращением и прокачкой рабочей жидкости через внутреннюю полость. Станки позволяют выполнить отверстия малого диаметра от 0,15 мм до 6,0 мм, глубиной до 300 мм (глубина зависит от диаметра электрода), при этом значительно быстрее традиционных методов, а также «сверлить» там, где получение отверстий механическим способом практически невозможно. Можно сверлить отверстия в наклонных, сферических и изогнутых поверхностях. С их помощью можно получить точные концентрические отверстия, проводить обработку под углом, избегать деформаций на входе и выходе, выжигать сломанные метчики, сверла и болты. Наиболее полно возможности данных станков раскрываются в электронной, авиакосмической промышленности (прошивка отверстий диаметром от 0,15 мм в труднообрабатываемых материалах – твердых сплавах, закаленной стали и т.д.), а также двигателестроительной, инструментальной, ювелирной, в изготовлении медицинского оборудования и во многих других областях. Но в первую очередь, данные станки используются для сверления стартовых отверстий в заготовках деталей с последующей обработкой на электроэрозионных проволочно-вырезных станках.

Технические характеристики

Максимальные размеры детали

Используемый диаметр электрода

Максимальный вес заготовки

Размер рабочего стола

Перемещения по осям (XxYx Z)

Генератор импульсов

Максимальный рабочий ток

Система управления

Максимальная скорость сверления

Минимальный износ электрода

Объем бака диэлектрика

Степень фильтрации рабочей жидкости

Количество фильтров

Полная подключаемая электрическая мощность

Давление сжатого воздуха

810x510x240 мм

0,3–3,0 (0,15–6,0) мм

300 кг

450x260 мм

400х250х370 мм

HCD

50 А

контроллер

40 мм/мин

20 %:

30 л

6 10 мкм

1

6 кВА

0,5–0,7 Мпа

Сварочный вращатель RWP small (Интертехприбор).

RWP POTTER – это сварочный вращатель с высотой планшайбы 280 мм и грузоподъемностью до 25 кг. Плюс данного устройства состоит в том, что скорость вращения зафиксированного металлоизделия может настраиваться мастером-сварщиком индивидуально. Она должна в точности соответствовать скорости формирования конкретного шва. Конструкция имеет прочный стальной корпус с механизмом вращения на который может быть установлена, как стандартная планшайба с канавочными пазами, так и универсальный зажимной патрон непосредственной на ротор.

Планшайба имеет электропривод наклона планшайбы от 0° до 110° для обеспечения оптимального положения сварки, скорость вращения от 0,4 до 15,00 об/мин. На корпусе вращателя имеются точки крепления для установки суппорта сварочной горелки.

Каждый позиционер по умолчанию оснащен блоком управления автоматической сварки R2. Контроллер позволяет управлять циклом сварки, находить нулевую точку и обеспечивает работу пневматического подъема сварочной горелки.

Универсальный токарный станок с ЧПУ Haas TL-1

Универсальные токарные станки сочетают функциональность современных станков с ЧПУ с простотой ручных универсальных станков. Благодаря системе интуитивного программирования операторы станков с ручным управлением легко переходят на работу с ЧПУ. Станки позволяют выполнять все токарные операции: наружное точение цилиндрических и фасонных поверхностей, внутреннее растачивание, сверление, нарезание метрической и дюймовой резьбы и др.

Максимально устанавливаемый диаметр заготовки над станиной, мм

Максимально устанавливаемый диаметр заготовки над кареткой, мм

Расстояние между центрами, мм

Максимальный обрабатываемый наружный диаметр, мм

Макс. длина обработки при точении между центрами, мм

Параметры шпинделя

508

279

762

406

762

Посадка шпинделя

Максимальная частота вращения шпинделя, об/мин

Максимальный крутящий момент на шпинделе (при n=355 об/мин), Нм

Максимальная мощность на шпинделе, кВт

Диаметр отверстия в шпинделе, мм

А2-5

1800

146

7,5

58

Параметры подач

Величина рабочих перемещений по оси ОХ, мм

Величина рабочих перемещений по оси ОZ, мм

Максимальная скорость холостых перемещений рабочих органов по оси ОХ, м/мин

Максимальная скорость холостых перемещений рабочих органов по оси ОZ, м/мин

Максимальные допустимые усилия по оси ОХ, кН

Максимальные допустимые усилия по оси ОZ, кН

203

762

11,4

11,4

17,32

8,66

Параметры точности

Параметры рабочей зоны

Точность позиционирования суппорта, мм

Повторяемость позиционирования суппорта, мм

±0,010

±0,005

Параметры устройства ЧПУ

Тип устройства ............................................................................................................................ HAAS

Количество управляемых осей ..............................................................................................2

Тип монитора для отображения информации ..................................................................LCD 15″

Скорость обработки программ, блоков/сек ...................................................................... до 1000

Тип интерфейса для подключения съемных носителей памяти ...............................USB

Объем памяти для хранения программ, Гб ........................................................................1

Минимальная дискретность задаваемых значений, мм................................................0,001